Sterillium® – more than just a hand disinfectant

On this blog, we regularly address hand hygiene and explain how various Sterillium® products help prevent infections in both the healthcare and private sector. Rarely, however, do we get to hear from the people who make Sterillium® the quality product we know today and who, day after day, turn this brand into something so indispensable.

In this interview, Hossein Gouhari (Senior Product Manager Hands & Skin), Felix Krause-Kyora (Senior Scientist Product Development) and Tomasz Sadowski (Clinical Expert) explain what makes Sterillium® so unique. They also reveal what the brand means to them personally, and when they themselves reach for the bottle with the iconic blue colour.

Sadowski: For me, hand disinfection is a cornerstone of the modern world. The development of disinfectants has led to a decisive improvement in overall living conditions – not only in hospitals, but in all areas of society in general.

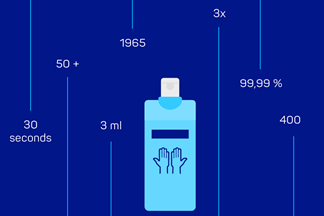

Krause-Kyora: It is a real milestone that we can easily use hand disinfectants to protect particularly vulnerable groups of people such as newborns or the sick, for whom exposure to germs can be particularly problematic. In only 15-30 seconds, we can rid our hands of pathogens and take very good care of vulnerable groups. This is an enormous achievement.

Gouhari: It makes you proud when the brand you work for becomes synonymous with the product. In many countries, the characteristic blue of Sterillium® has become a sign of high-quality hand disinfection. This has led to more and more competitors copying the colour in their products. In India, for example, propanol-based disinfection products are always blue. I think this clearly shows how respected Sterillium® is in many parts of the world and that it is perceived as a global standard.

Krause-Kyora: It is wonderful to be part of a brand that has played an important role in the lives of several generations and many people associate it with certain emotions. Through its unique smell, Sterillium®, like sunscreen or certain foods, awakens very specific associations and memories in people.

"It fills me with pride to work on a product that is so desperately needed."

Sadowski: At Sterillium® we work on a product that fulfils a very important task in the private, and, in particular, the medical sector - namely to prevent infections. Especially at the beginning of the pandemic, I noticed how meaningful it is to have a role with such social relevance. It fills me with pride to work on a product that is so urgently needed.

Gouhari: Sterillium® also helps people in the medical field stay healthy and work in a way that prevents them from getting sick from what they do. After all, a high-quality hand disinfectant like Sterillium® not only protects vulnerable groups such as patients but can also ensure that nurses and doctors remain fit for work thanks to its skin-friendly properties.

Gouhari: In a normal working day, a nurse disinfects her hands between 50 and 100 times. With so many daily applications, it is essential that the product does not stress the skin. Otherwise, in the worst-case scenario, it can lead to staff being unable to work due to skin diseases. Imagine you have studied medicine for 6 or 7 years, and then done specialist training to work as a surgeon, only to be no longer able to do this very job due to a skin intolerance.

Although such cases are rare, they do happen. During the pandemic, for example, hospital staff regularly used hand disinfectants based on the WHO formula. However, these products are often not particularly skin-friendly. The pandemic-related increased hand washing, as well as disinfection with such products has not infrequently led to skin irritation and eczema for many healthcare workers [1]. Such cases show how important it is to provide medical staff with a high-quality hand disinfectant such as Sterillium®, which is not only highly effective, but also has skin-caring properties and enables them to do their job in a way that keeps them healthy.

Gouhari: Surgeons are usually the most expensive employees in a hospital. Against this background, 1.5 minutes per operation per year can make a huge financial difference. You just have to do the maths: if a clinic performs 10,000 operations a year and always has at least two surgeons and a sterile assistant on duty, then 1.5 minutes less per person, per procedure per year already means a pretty big cost saving.

Krause-Kyora: We are constantly questioning the status quo to see where we can improve products and processes so that the products are also used with satisfaction. The goal is always to integrate the products better into everyday (professional) life.

Gouhari: Initially, the shortened exposure time of Sterillium® also met with some resistance, as the innovation was contrary to the established standard. Now, however, the 1.5 minute exposure is accepted and there are only products that are effective within 90 seconds in clinics. We have clearly set the trend by questioning the standard in the first place.

"With the shortened exposure time, we challenged the standard – and set a new trend."

Krause-Kyora: We will very soon be launching a new product, whose main innovation is the method of application. In many respects, this new product is an improvement compared to other disinfectants. One advantage is that, unlike liquid products, the new application method does not drip and, as a result, does not leave any residue on clothing or other objects. In addition, you can see where you have already applied the disinfectant and where you need to apply more. We have also developed a new care complex that contains ingredients that provide special care for the skin.

Sadowski: We have already tested the product extensively and conducted a large-scale clinical study with it. We were very pleased with the results. Both test subjects as well as dermatological experts confirmed the product's excellent skin tolerance and care properties.

"When developing disinfectants, especially hand sanitizers, one of the biggest challenges is that they should be effective and skin-friendly at the same time."

Krause-Kyora: We are very strict about selecting the right ingredients. For example, all materials for Sterillium® must comply with the standard approval for medicinal products in Germany. And we check this very meticulously – when receiving the ingredients, for example. Nothing is allowed on our premises that is not clearly labelled and has not been analysed beforehand. This analysis is carried out by us on site and by the suppliers.

We have very specific quality requirements. For instance, our suppliers must prove exactly where and how they produce the alcohol that we use in Sterillium® here in Hamburg. We double and triple check all raw materials before they are allowed to be processed. This is an enormous effort, which we are happy to take on ourselves so that we can guarantee a qualitative and safe product.

Krause-Kyora: The actual production is very mechanised, like many other companies. It starts with large tanker trucks arriving at our site with the raw materials, which are then emptied into special tanks on our premises. The liquids are stirred thoroughly in the tanks. You can imagine it a bit like a blender, the individual raw materials are added from above or below according to the respective recipe - and then mixed well like they are in a thermomixer.

Gouhari: Finally, after filling into the bottles, there is one last quality assurance. We check the ingredients not only before the production process, but also in the middle and after. Every batch is microbially tested after production and only if this analysis is positive, is the product released.

Sadowski: On the one hand, there are specific triggers or requirements from our customers, such as hospitals or hygienists. We want to meet these needs through the optimisation or development of products. On the other hand, there are also new findings from science that can either be incorporated into existing products or lead to completely new applications.

Krause-Kyora: We do not only develop individual products such as disinfectants, but also holistic hygiene solutions for hospitals and other institutions. This includes applications to improve hand hygiene compliance. A good example of this is our special disinfectant dispensers, which are equipped with Bluetooth trackers to make it possible to see exactly where it is important to place dispensers in the clinic.

Sadowski: New applications can also have the purpose of convincing our customers of the positive properties of our Sterillium® products. For example, we recently established a new method for measuring skin moisture. The principle behind it is quite simple: you scan the skin with the device and then see on the screen how much moisture is present in the skin. The brighter the image, the moister the skin.

Sadowski: The three of us are family men and know how much dirt children can bring home. That's why I often disinfect my hands with classic Sterillium® after going to the playground or changing nappies. In addition, we also use surface disinfectants to maintain hygiene in the home.

Gouhari: I also frequently use classic Sterillium® too. For example when my children have caught another stomach bug, I will disinfect my hands very often with it. When I open the bottle, it always brings back memories. I used to work in a clinic myself and have fond memories of that time. As soon as I catch that characteristic smell, I immediately think back to that beautiful phase of my life.

[1] Reinholz M et al. (2021) Increased prevalence of irritant hand eczema in health care workers in a dermatological clinic due to increased hygiene measures during the SARS-CoV-2 pandemic. Eur J Dermatol;31: 392-395. https://doi.org/10.1684/ejd.2021.4046

Use disinfectant safely.

Always read the label and product information before use.

[Please amend in accordance with local requirements (e.g. law of advertising, product status, CLP labelling)]